Dates & News

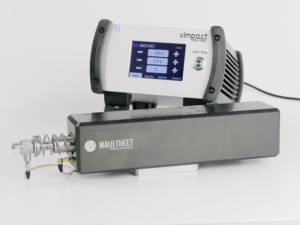

Our seminars, publications and exhibitionsWe have integrated a hit counter for the new models in our vImpact series.

This can be operated via a third field at the bottom of the display.

If the hit counter is at “0”, the hammer works as usual in an endless loop.

However, if you assign a number to it, it will be counted down and the hammer will stop automatically when it has expired.

This allows measurements to be carried out with a specified number of blows and excess hammer blows can be avoided.

This has a positive effect on the lifespan of the system.

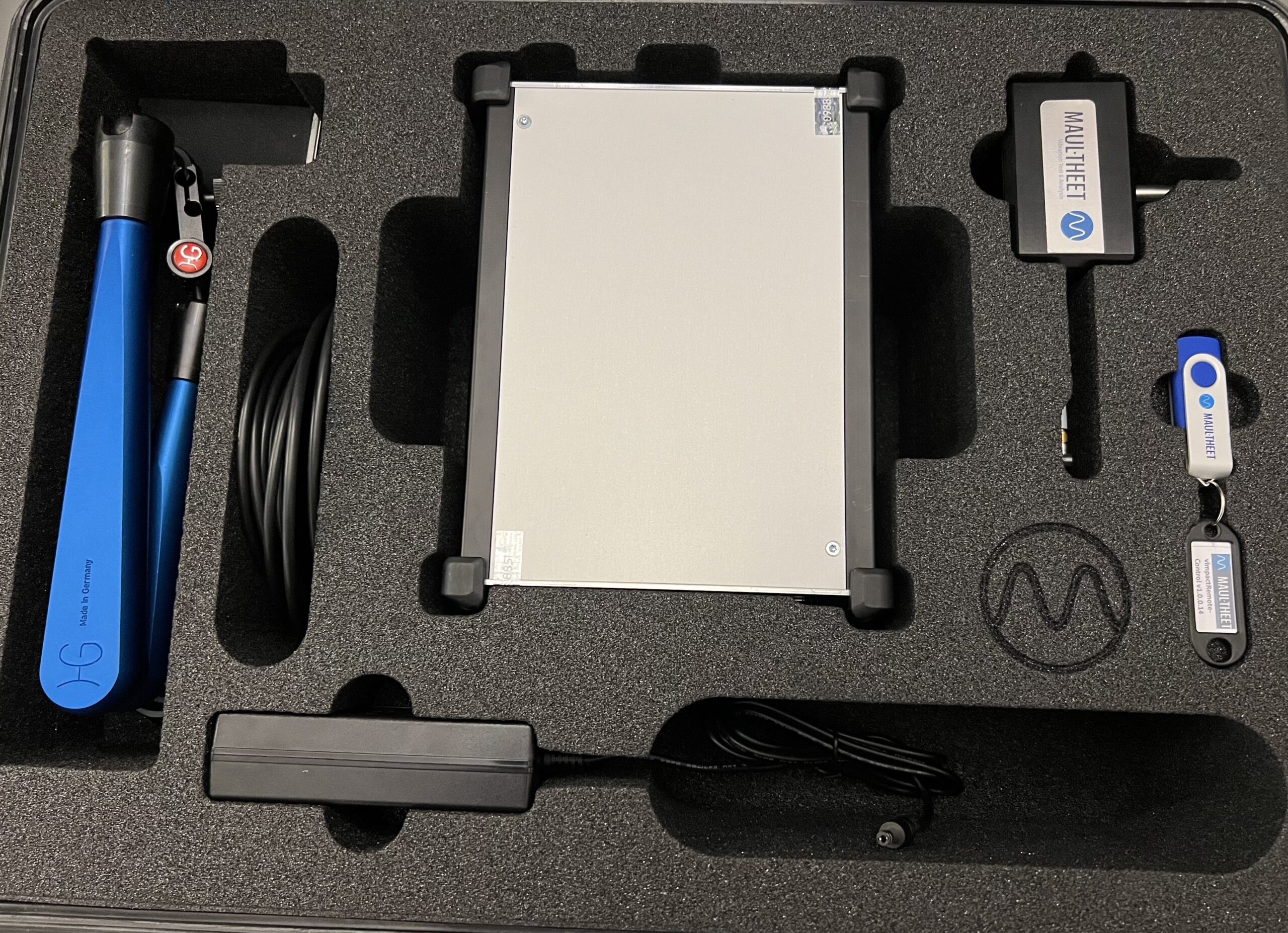

NEW! Accessories for our vImpact series!

We now have some accessories for our vImpact-Series in stock.

From the Hoopguard that protects the shaft of the vImpact-63 to super flexible BNC cables in all desired sizes,

to the TriggerBox with which you can trigger any vImpact.

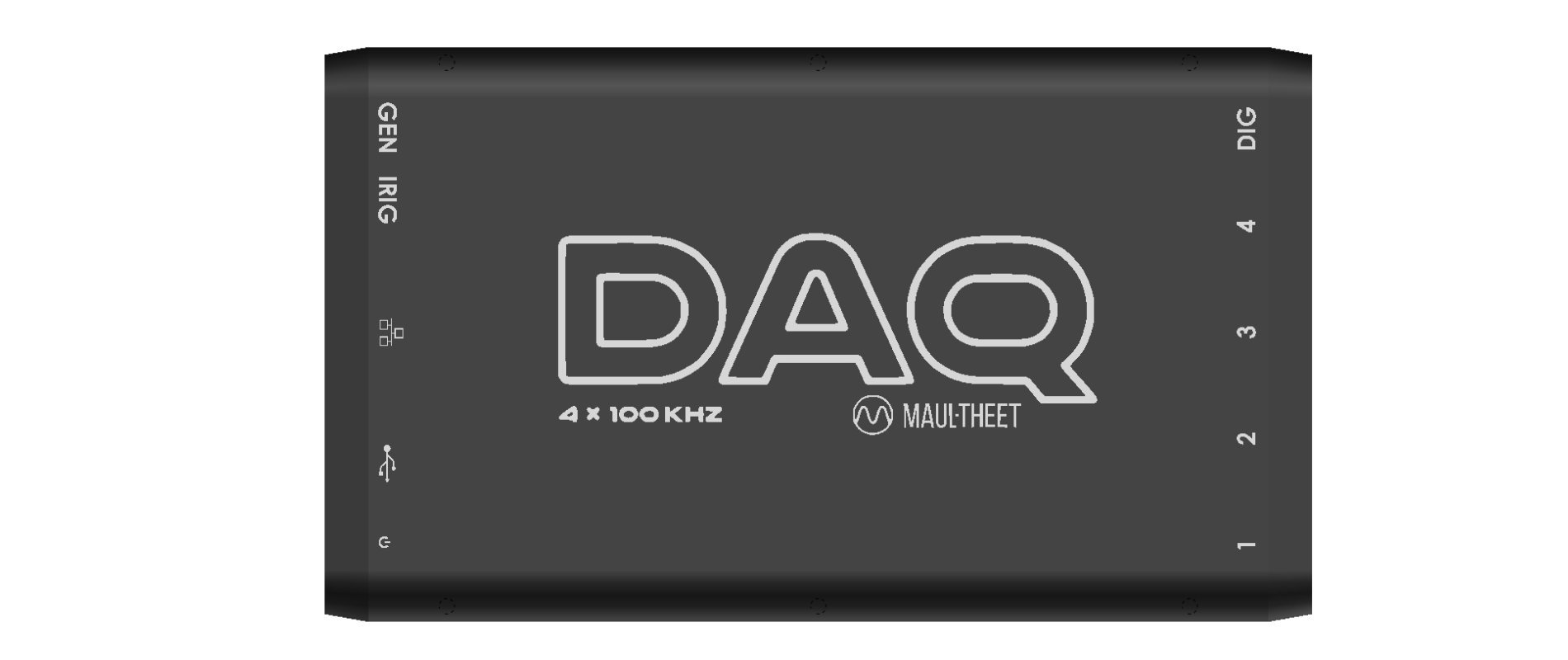

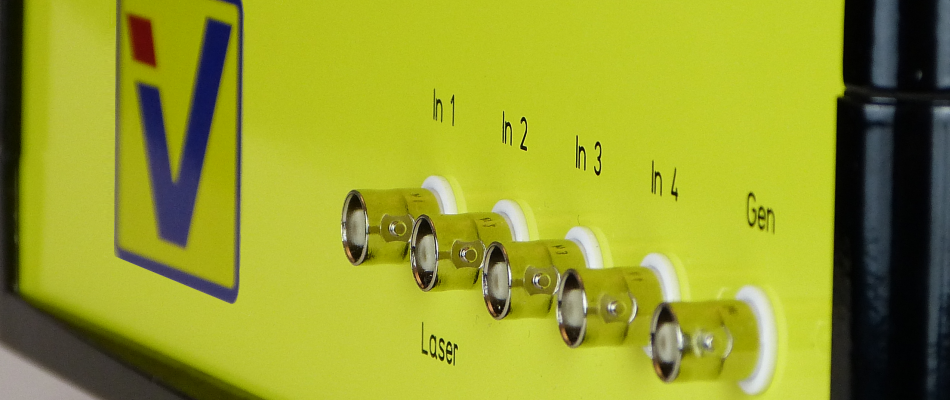

DAQ 4×100 SOON IN STOCK!

Instead of 20kHz 4 channel or 80kHz 3 channel without generator, there is now 100 kHz 4 channel with generator USB-C and Ethernet!

The DAQ 4x100kHz is priced at the same price as the 20kHz card, which of course makes it even more interesting for the market.

Everything comes in a robust aluminum housing which also protects the connections. Pre-orders can be made as the first DAQ 4x100kHz are expected to arrive in early 2024.

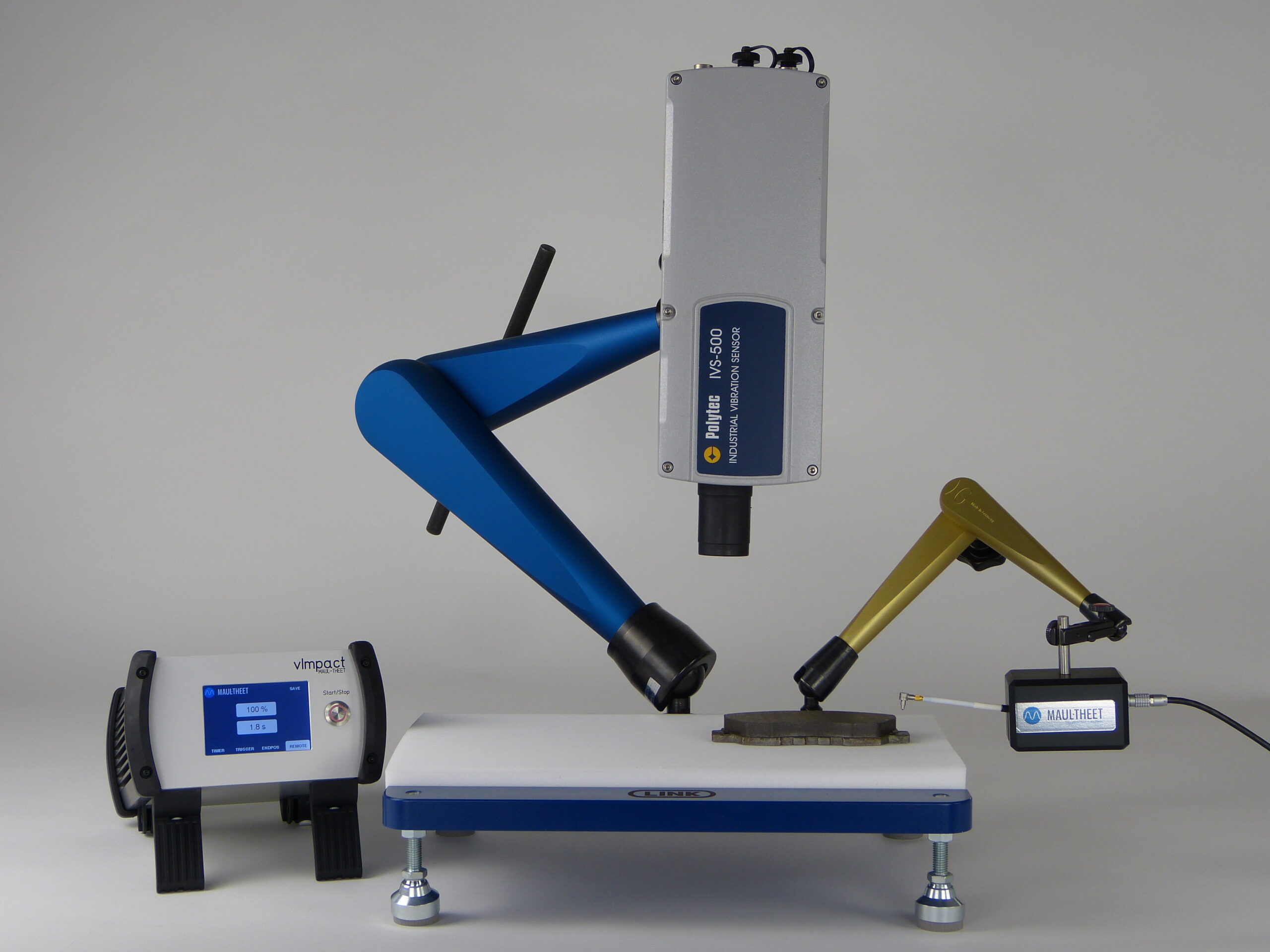

Have you ever determined the natural frequencies and damping of a component? No? No problem!

The NFT does that for you! Simply specify what type of test item you want to measure,

specify the serial number, name, etc. as required.

Align the hammer and laser according to a specified photo and start the measurement with a mouse click.

Print or send the evaluation as desired.

A measurement can be that simple.

It will soon be very, very cold! vImpact-63 UPGRADE!

Until now it was possible to order the vImpact-63 as an ICE version, which made it suitable for climate chambers.

This is no longer necessary from now on!

All new vImpact-63 are now suitable for climate chambers.

In collaboration with the company Hörger&Gässler, we had the matching mechanical laboratory arms produced in Maul-Theet blue. Up to now we have had the hydraulic laboratory arms in gold, which can hold a higher weight but cannot be used for the climate chamber due to the hydraulic fluid.

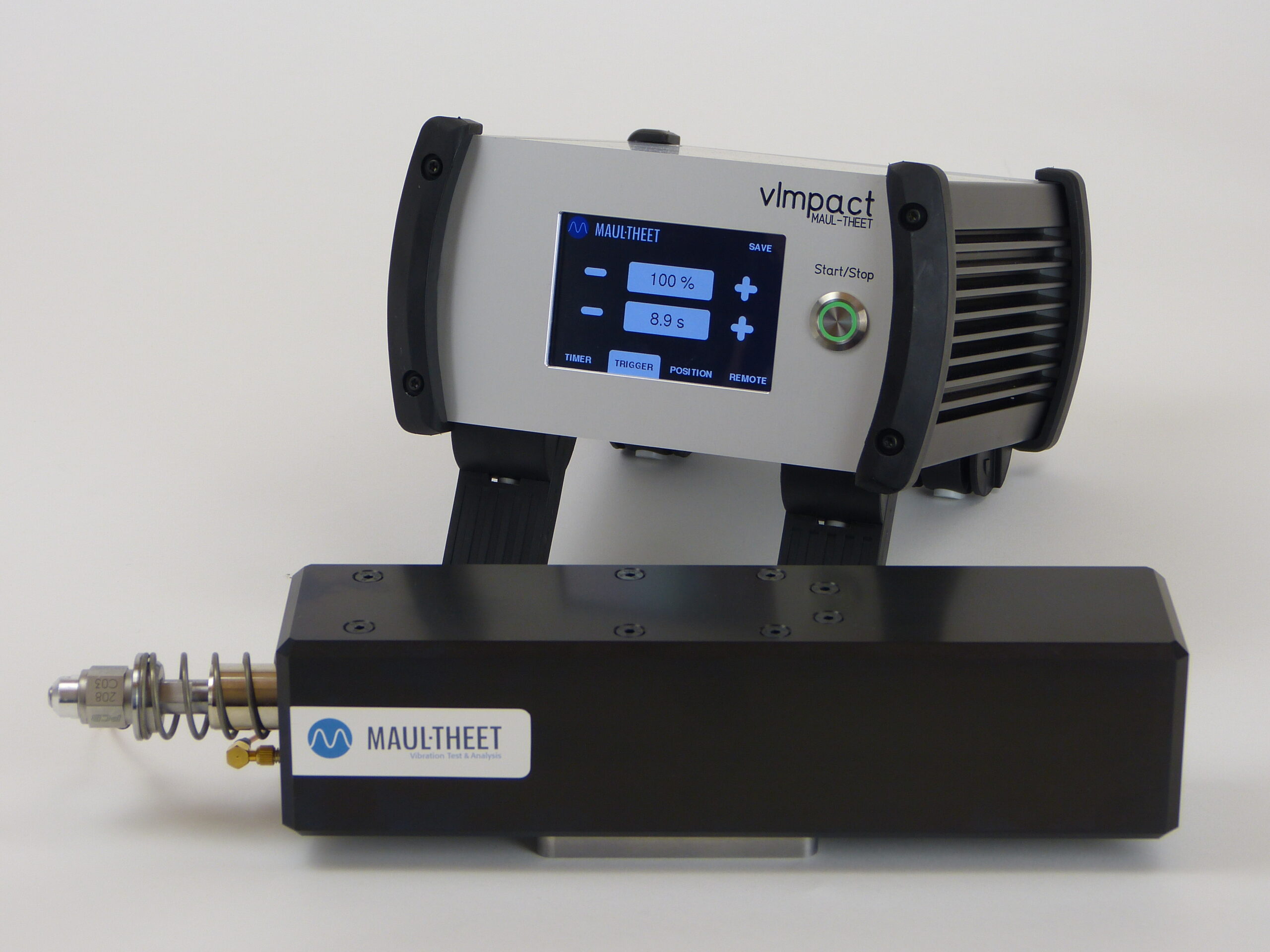

READY TO ORDER the new vImpact-2003c ?

The advantages of the new vImpact-2003c (compact)

We made it!

Our newest Automatic Modal Hammer is the vImpact-2003c!

The vImpact-2003c has lost 3kg compared to its predecessor, the vImpact-2003.

Its external dimensions have shrunk from 80x80mm to 60x60mm.

The length has now also been shortened to 320mm including the measuring cell.

We did all this without losing peak power or other functions.

The reduced dimensions and weight mean that the hammer is now easier to set up.

There is a second Built-in socket for the connection cableto get even better

to spatially limited measuring points in the base plate.

Compared to the vImpact-2003, this shortens the length of the built-up hammer by another 100mm.

LINK and Maul-Theet to Enter Exclusive Strategic Partnership!

Link Engineering Company (LINK), a premier provider of customized testing equipment, and Maul-Theet, a leader in structural dynamics for more than 25 years, are excited to announce that, effective February 2023, they have entered into a strategic partnership. Moving forward, LINK will leverage their global presence and begin marketing, sales, and support initiatives for the Maul-Theet product line at all LINK sites.

January 2023 comes the NEW! 100kHz 4 channels USB & Ethernet

Soon it will be time and the vMeas standard 20kHz 4 channel card

becomes an antique!

Our new measuring card delivers a multiple of performance and features in the same price segment.

Our ScanSet will also benefit from this.

The vMeas 2.0

- 100kHz

- 4 channels

- 24bit

- Anti-aliasing filter

- IEPE (2-4mA)

- USB connection

- Ethernet connection

- Power over USB

- Power over Ethernet

- Synchronous sampling

- Cascadable

ScanSet-100kHz

With the new 100kHz card we also say goodbye to the 20kHz and the 80kHz ScanSet.

What does that mean for our customers?

Maul-Theet remains true to its pricing policy!

For the price of a 20kHz ScanSet you now get a 100kHz!

Available from February 2023.

The “vImpact” family is growing!

The classic vImpact hammers vImpact-63 and vImpact-2003 are the first choice for many applications and are very popular with your users.

However, there are cases where the automatic modal hammers reach their physical limits. That’s why Maul-Theet is always developing new models for the vImpact family.

Coming soon:

The vImpact-Gravity

This vImpact is a pendulum hammer that is automatically lifted and dropped. After hitting the object, the hammer is intercepted to avoid “double hits”. This hammer allows measurements and quality checks to be carried out on very soft surfaces such as musical instrument strings.

The vImpact-Compact

We are in the process of downsizing the vImpact-2003 without sacrificing functionality or power.

The vImpact-Automatic

This automatic modal hammer should make it possible to position and set up yourself.

The field of application of the vImpact should be the completely autonomous testing of products in series production.

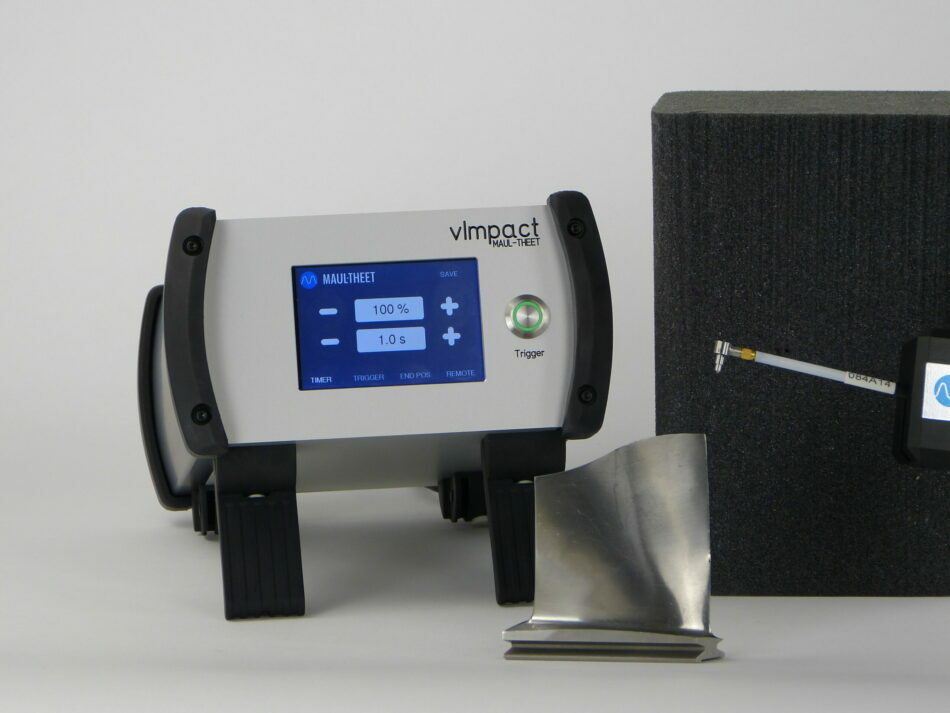

The automatic hammer “vimpact” now digital!

The new vImpact hammers are now digital with a touchscreen. This has many advantages for the user:

- Remote controllable via “vImpact Control Software” or ASCII commands

- Settings can be saved

- Impact power adjustable from 0 to 100%

- Setup mode

- Countdown to shot in timer mode

The vImpact can now be integrated into test benches via the USB interface and controlled via software according to customer requirements.

“End Of Line Testing” with the vImpact

Maul-Theet offers individual remote software solutions for the needs of customers.

For end of line testing for different measurement objects, it is possible to document the hammer setup (e.g. distance between the hammer tip and the measurement object) and to save the corresponding hammer settings.

If desired, the measurement objects can then be selected manually or with a QR or barcode scanner.

vImpact

Maul-Theet goes “indoor”

Due to our long term experiences in vibration measurements and structural dynamics we can offer you seminars with content adjusted to your applications and in your location. This “indoor” seminars may handle topics like:

- Basics in vibrations, signal- and system analysis

- Methods of spectral analysis

- Measurement chain and practical signal analysis

- Modal identification

- Practical measurements

Length and content of a seminar can be adjusted to your needs. Please contact us for further information.