Automated Modal Analysis | AMA

The automated modal analysis enables the user to automatically measure a very large number of points over a long period of time.

Once set up, the system works independently without further supervision.

Applications & Integrations

Research and Development

Machine diagnostics

Model updating

Structural dynamics

Determination of resonances

Eigenvalue identification

Operating deflection shapes

Structural modification

Sensitivity analysis

Proto type testing

End of line testing

AMA | SAEJ2933

Advantages & Innovation

Cost and time savings due to low personnel costs

High measurement quality

Reproducibility

Large number of degrees of freedom

Short measurement times

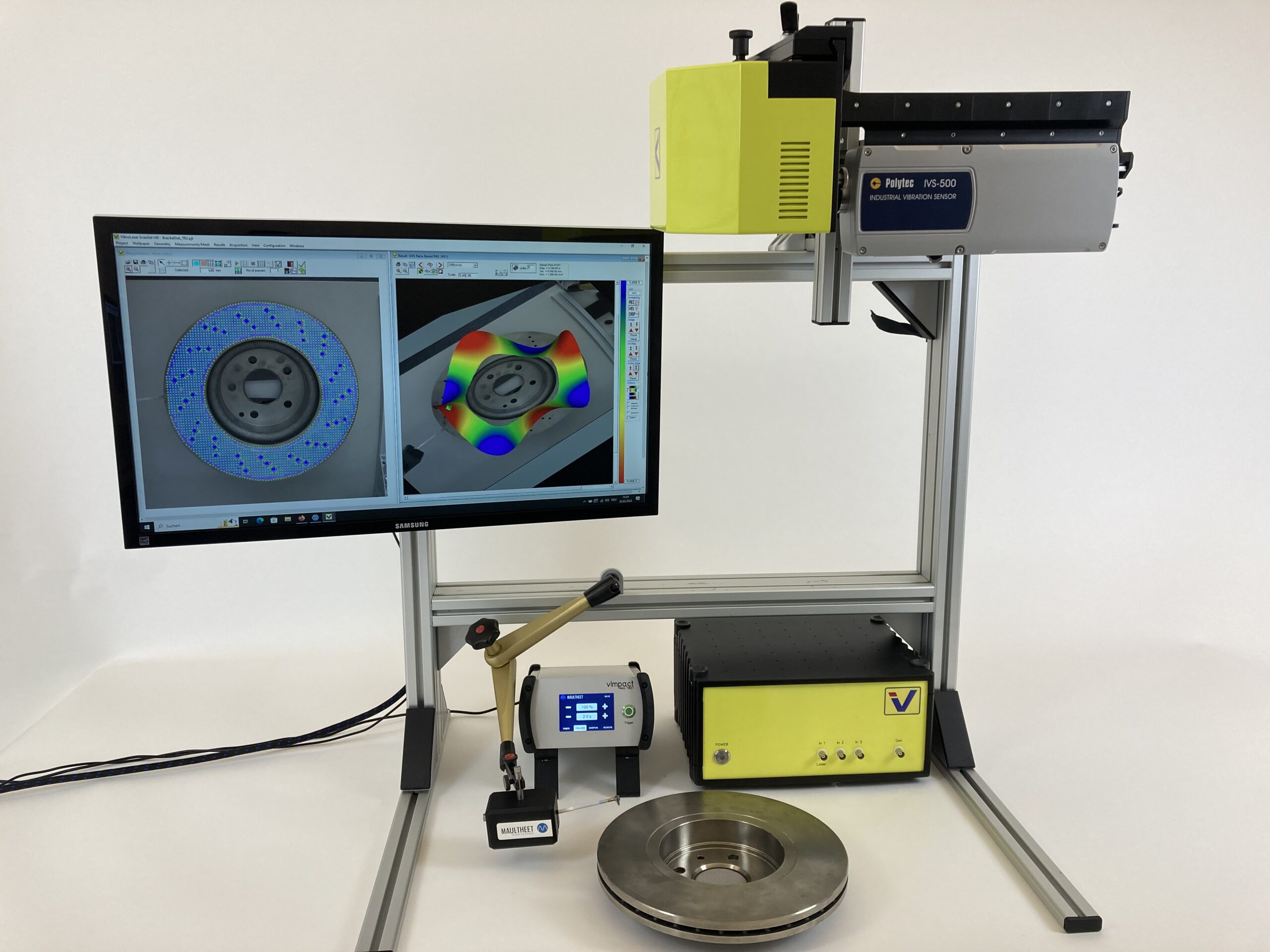

Components

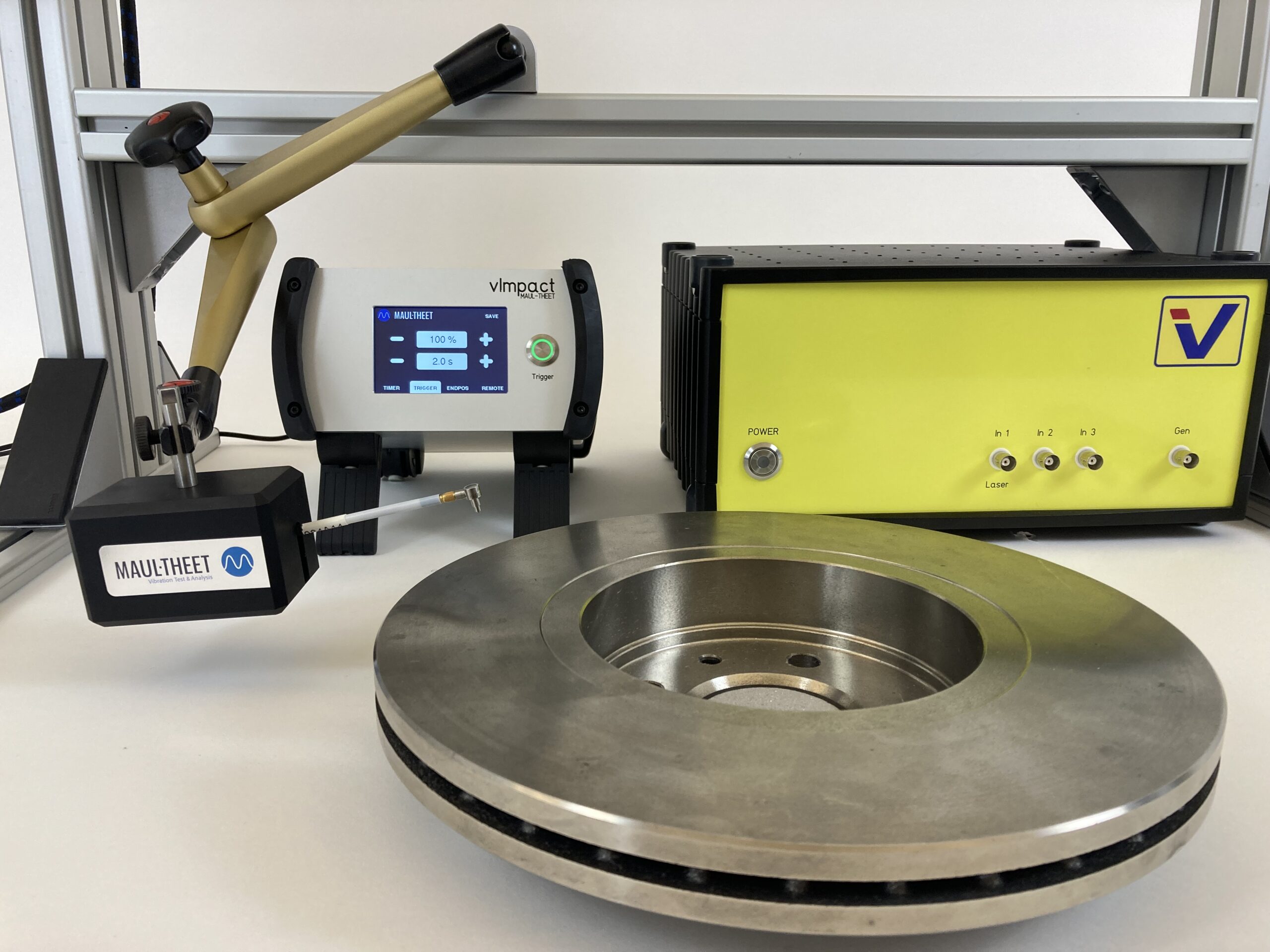

Automatic Modal Hammer

VibroLaser ScanSet

Software vModal

Test Stand Portal

Commercially available Laser Doppler Vibrometer

Characteristics

Flexible Setup and Positioning of components for various test objects

Automated determination of large number of Frequency Response Functions without necessity of personal test surveillance, e.g. over night measurements“

By using the Automatic Modal Hammer only very few application efforts necessary and therefore time and costs saving setup For Your Requeir