Scanning Laser | ScanSet

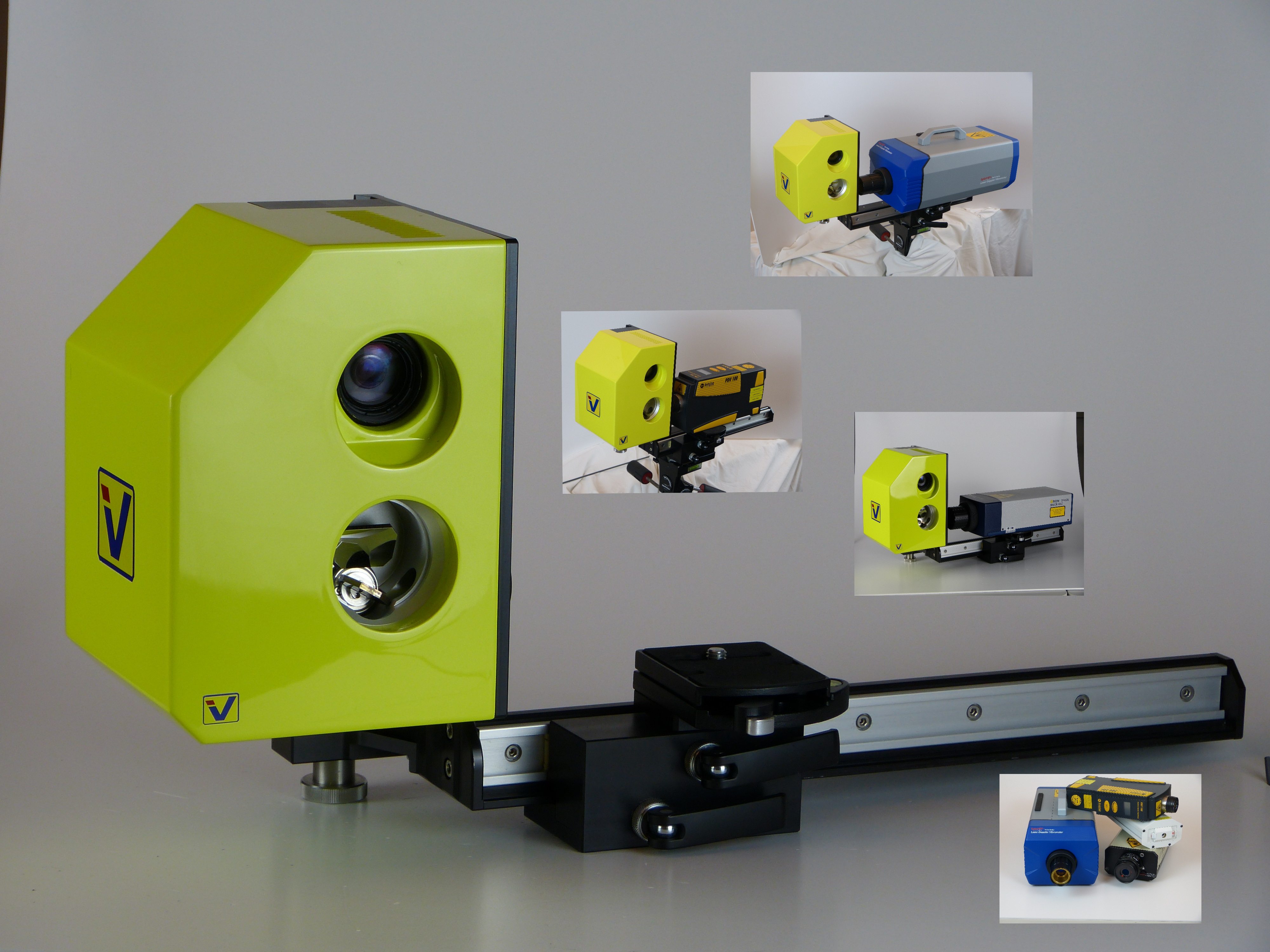

With the Scanning Laser Doppler Vibrometer, the laser beam is positioned using two computer-controlled mirrors. The measurement points are defined interactively on the video image of the measurement object. The vibration measurement is automatically carried out by the computer at the specified points. In comparison to complete systems, the developed ScanSet can be operated with different laser vibrometers. It turns a standard single-point laser vibrometer into a fully-fledged scanning laser vibrometer in just a few simple steps. To do this, the single point laser vibrometer is simply fixed using the quick-action clamping devices and the measurement can start. The ScanSet has its own data acquisition with analog inputs for measuring the laser and reference signals. The user-friendly measurement and analysis software enables evaluation of the vibration data including graphical vibration shape animation in short time.

Advantages & Innovation

Pricing at less than 50%-80% of available scanning systems on the market

Existing/Old SinglePoint Laser can be reused

Works with all common Single Point Laser Doppler Vibrometers

Direct interface/data transfer to the vModal software

Operating deflection shape analysis in the time domain

Inexpensive, fully-fledged SLDV

Swiveling CDD camera

User-friendly software

Data acquisition can also be used as a simple FFT analyzer

Mobile measuring system

Use of different LDV depending on the application

Generator output for controlling excitation systems (shaker)

Hightech Innovation Made in Germany

Applications & Integrations

Visualization of wave propagations

Experimental modal analysis

Research and Development

Optimization of development-accompanying simulations

Test benches

Series testing

Quality control

VibroLaser Scanset Components:

ScanSet

The VibroLaser ScanSet is manufactured from robust aluminium, and has next to the high precision laser deflection unit a CCD-Camera for photo realistic capture of the measurement object. To ensure that the laser beam of any usual Laser-Vibro meter exactly hits the mirror axis in zero position, the VibroLaser ScanSet offers linear slides that can be easily fixed by clamping lever to ensure a precise and reliable laser positioning. Using a ScanSet for measuring the signal quality is only dependant on the specifications and quality of the used Laser Doppler Vibrometer. The electrical connection to the controller is simply realized by a single cable that also supplies the mirrors with power, takes care about the mirror and camera steering and carries the measurement data and CCD-Camera Signals.

Controller

The controller includes next to the power supplies, an electrical component to steer the mirrors and a data acquisition system to digitize the vibration signals. The controller has a direct connector for the central cable to the ScanSet, BNC connectors for the input channels and the generator output and one USB connector to communicate with measurement PC. The Notebook/PC is only connected with one USB-cable for mirror and CCD-Camera steering, vibration data and video stream.

Software

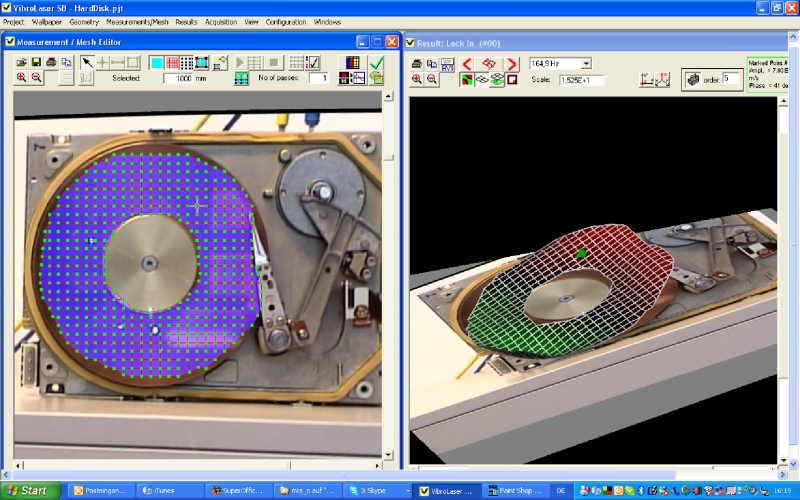

The measurement and analysis software includes all necessary modules to do complete scanning jobs such as:

CCD-Picture capture, Live Display

Geometry and Measurement Point Editor

FFT Analyzer with extensive functionality

Mirror control and steering

Operation Deflection shapes (ODS)

Animation, AVI-Export,UFF– , ASCII– and MatLab- Export

Free Offline-Version to use in office

Modal analysis module (optional)

Operation system Windows10

NEW! Module for ODS in time domain (optional)

Technical Data

| Typ | ScanSet-20 kHz | ScanSet-80 kHz | ScanSet-2 MHz |

|---|---|---|---|

| No. of Channels | 4 | 3 | 2 |

| A/D converter | 24 Bit | 24 Bit | 16 Bit |

| Frequency ranges | 1 Hz - 20 kHz | 1 Hz - 80 kHz | 1 kHz - 2 MHz |

| Frequency resolution | 25 600 FFT Lines | 25 600 FFT Lines | 25 600 FFT Lines |

| Input ranges | ±1 V, ±10 V | ±1 V, ±10 V | ±2,5 V |

| Coupling | AC, DC, IEPE | AC, DC, IEPE | DC |

| Anti-Aliasing Filter | adjusted to frequency range | adjusted to frequency range | adjusted to frequency range |

| Generator output | Sine, Chirp, Noise and Step Sine | Sine, Chirp, Noise and Step Sine | Non |

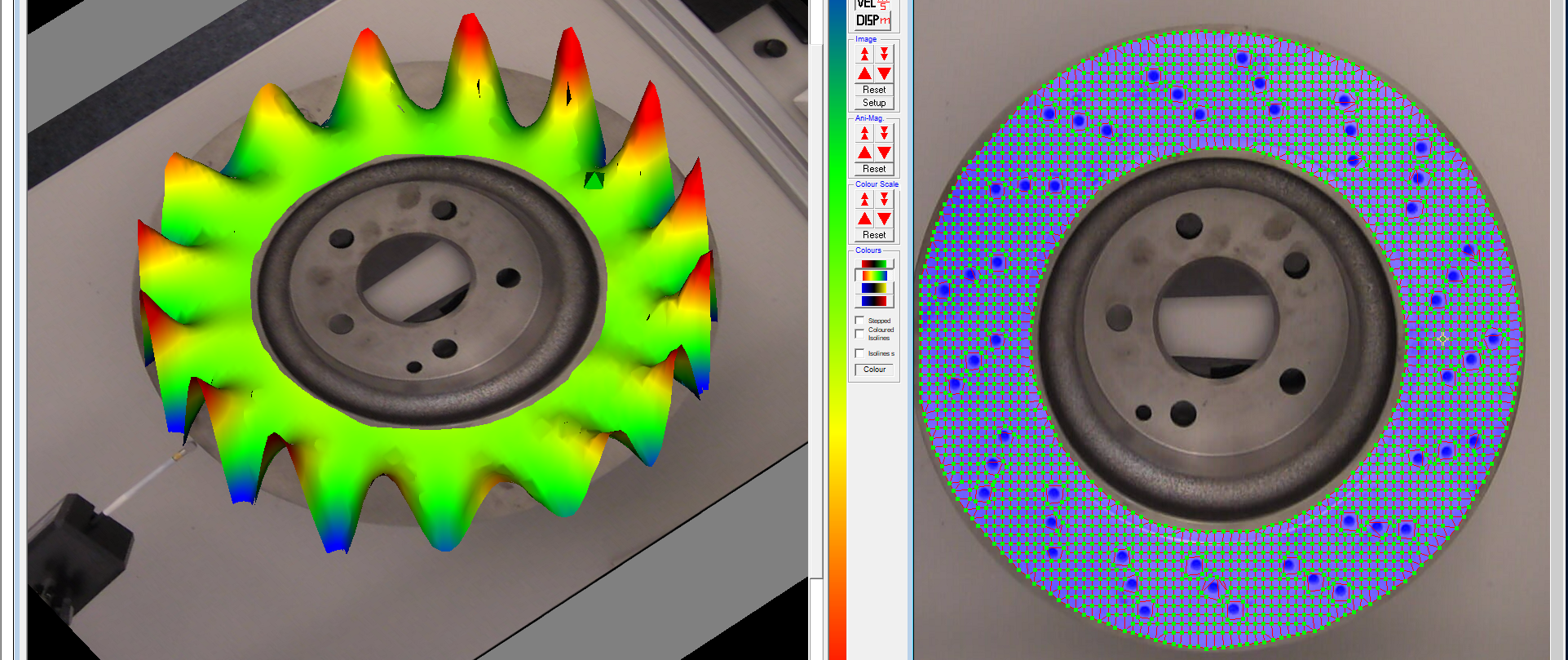

Module for ODS in time domain

Reproducible transient operations can be measured and saved sequentially with the ScanSet. If the measurement are triggered with a reference channels, the single channel measurements can be combined to a multi-channel-measurement with synchronous time series. This signals can be played back as animated time movie. The transient movement of technical structures can be shown in slow motion. Typical applications are:

Animation of wave propagation in technical structures

Fault detection in composite materials (Delamination)

Presentation of periodic movement of machine parts

The example shows the wave propagation in a brake disc after impact excitation measured with 2500 single point measurements.

(See video ScanSet wave propagation)