Hardware

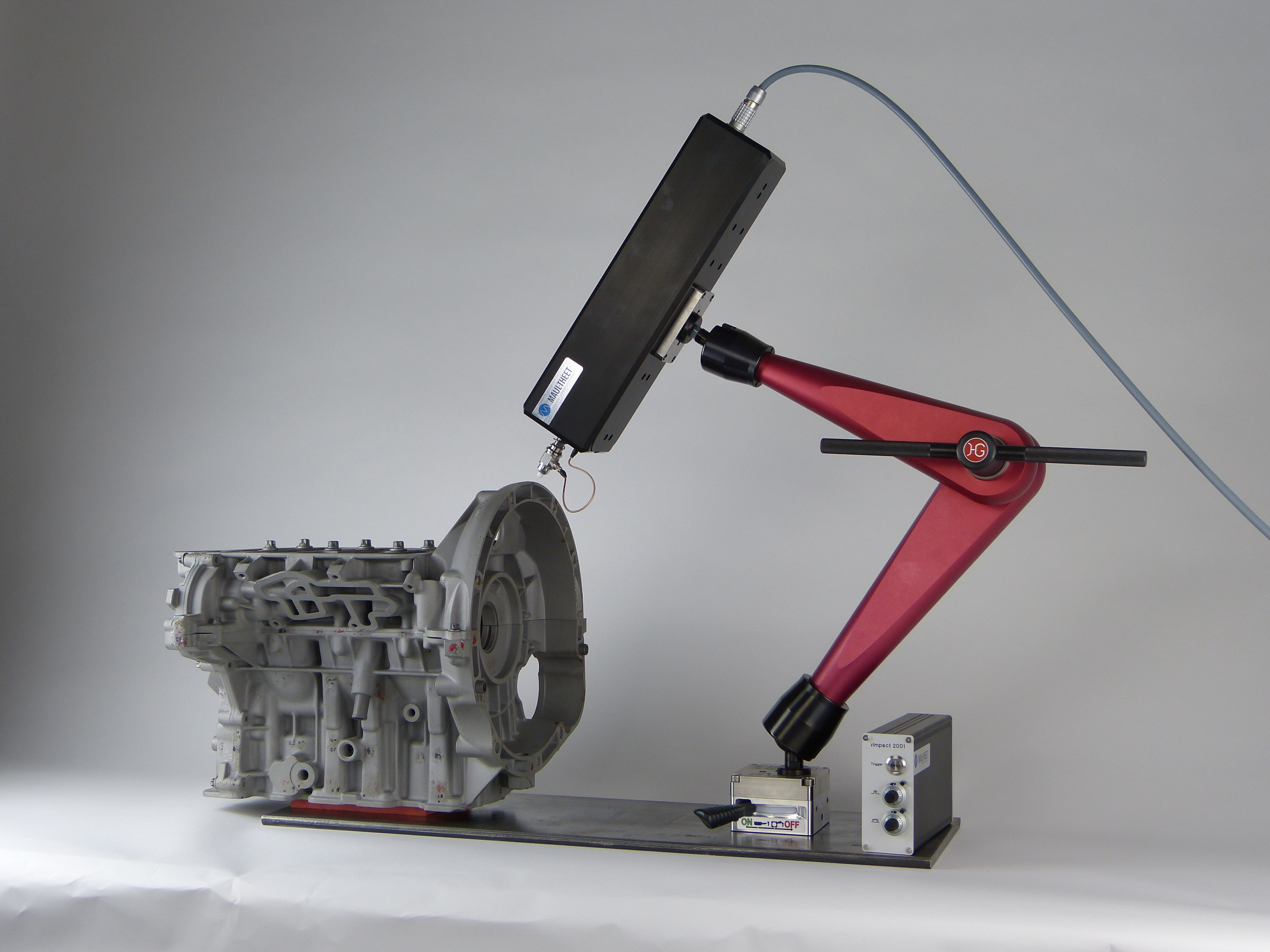

A manual excitation with a small Modal Hammer without a „Double Hit“ is nearly impossible – a well-known and very inconvenient issue. As solution for this issue MAUL-THEET developed the product-series of Automatic Modal Hammer “vImpact”. This enables you to precisely and reproducibly excite structures and measure the excitation forces.

The product-series of Automatic Modal Hammer from MAUL–THEET includes the vImpact–20 and the vImpact–60. The difference lies mainly in the performance of the measuring range – the vImpact–60 to max. 60 kHz, the vImpact–20 measures up to 20 kHz.

vSpeedBox

Rotational-speed sensor with Voltage and TTL output. In many experiments and measurements it is necessary to precisely detect the speed. Especially for the depiction of the speed dependent waterfall diagrams or speed dependent measurement values (e.g. order analysis), the recording is absolutely necessary.

ScanSet

The laser beam of the Scanning Laser is deflected by two mirrors which are controlled by a computer. The measurement points are positioned directly on the video picture of the measuring object.

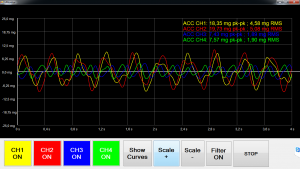

vMonitor

With vMonitor, MAUL-THEET offers a flexible system for permanently recording the vibrations of buildings. Particular emphasis is placed on multichannel vibration measurement of small amplitudes in the low frequency range (<3 Hz). Due to the continuous recording of the vibration signals, an analysis of the measurement data can also take place backdated over a long period of time.

VTS frequency test stand

The vibration test stand was specially designed for the high-precision determination

of blade resonances and modal parameters with minimal influence of the clamping on the results.

– Hydraulic clamping device with PLC control

– Precise determination of blade eigen frequencies

– Export to Excel, ASCII or SAP

– Blade database

– Scalable for custom blade sizes

ATS Airflow test bench

The air mass flow measurment method using supercritical nozzles offers the possibility to measure very precise the mass flow through turbine blades, blast pipes and other test objects such as e.g. gas burners. This test benches are compact and include in addition to the sonic nozzles and sensors, a PC for automated operation.

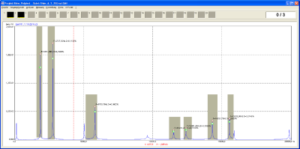

DTS Damping Determination

During the development and production of brake systems for the reduction of brake squealing damping materials so called shims are applied on the brake pads. For the comparison of damping characteristic of different shims test plates are measured according to company internal specifications. The specifications are usually based on a determination of the modal damping as a function of eigen frequency and temperature. MAUL-THEET offers a system in which the time-consuming measurements are automated and therefore deliver highly reproducible results.